UV Water Sterilisation

The Science of UV Light

Ultraviolet Sterilization is unmatched in its efficiency, simplicity, and dependability when applied as a microorganism disinfectant. UV sterilization is a proven solution to waterborne planktonic algae as well as other harmful pathogen problems. Certain critical UV performance factors greatly affect all UV sterilizers, no matter who’s the manufacturer. The information contained in this outline should be considered before purchasing any UV equipment.

Factors Influencing UV Effectiveness

Whether you choose to label a UV as a clarifier or a sterilizer, the same design, performance, and operating principals apply. Successful UV operation destroys the targeted microorganism. Here are five main factors that will help determine the ability of a UV sterilizer (or clarifier) to achieve this desired effect.

1. The type of lamp used in the application. (low-pressure or medium/high-pressure)

2. The length of the lamp being used. (the ARC Length)

3. The physical design of the UV’s water exposure chamber.

4. The condition of the water being treated.

5. The water flow rate through the UV’s exposure chamber

The Science of UV

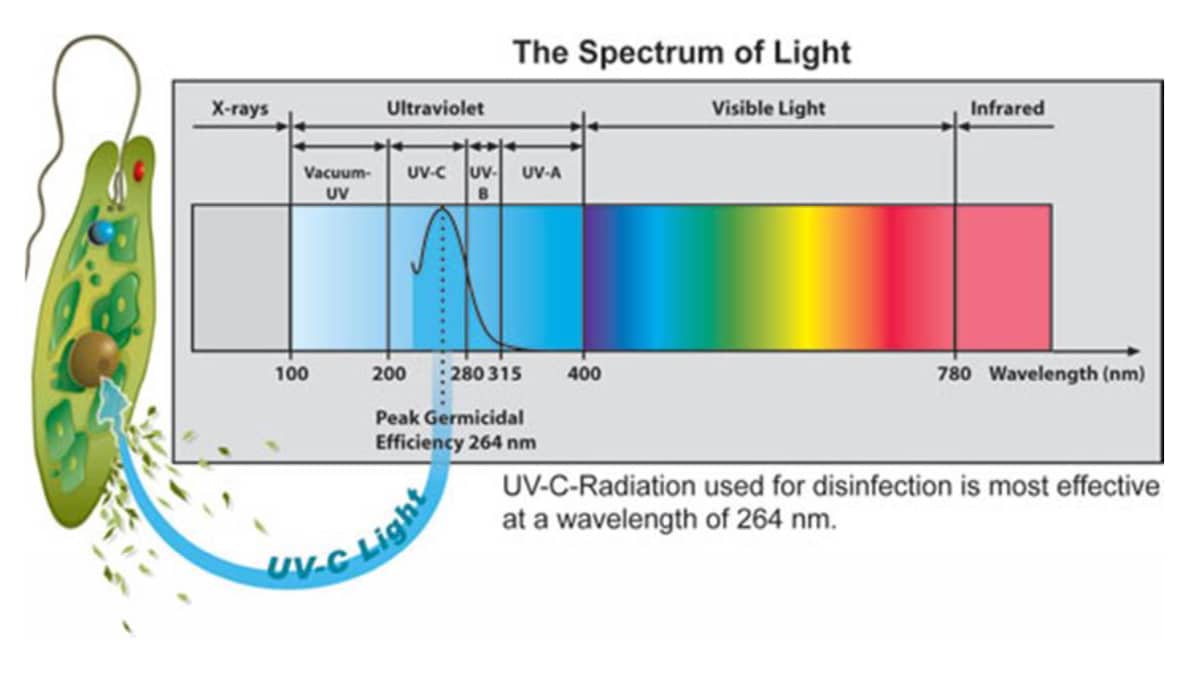

Let’s start at the beginning. Ultraviolet light is a spectrum of light just below the range visible to the human eye (below the blue spectrum of visible light in the chart above). UV light is divided into four distinct spectral areas- Vacuum UV (100 to 200 nanometers), UV-C (200 to 280 nanometers), UV-B (280 to 315 nanometers), and UV-A (315 to 400 nanometers). The UV-C spectrum (200 to 280 nanometers) is the most lethal range of wavelengths for microorganisms. This range, with 264 nanometers being the peak germicidal wavelength, is known as the Germicidal Spectrum.

The Targeted Microorganism

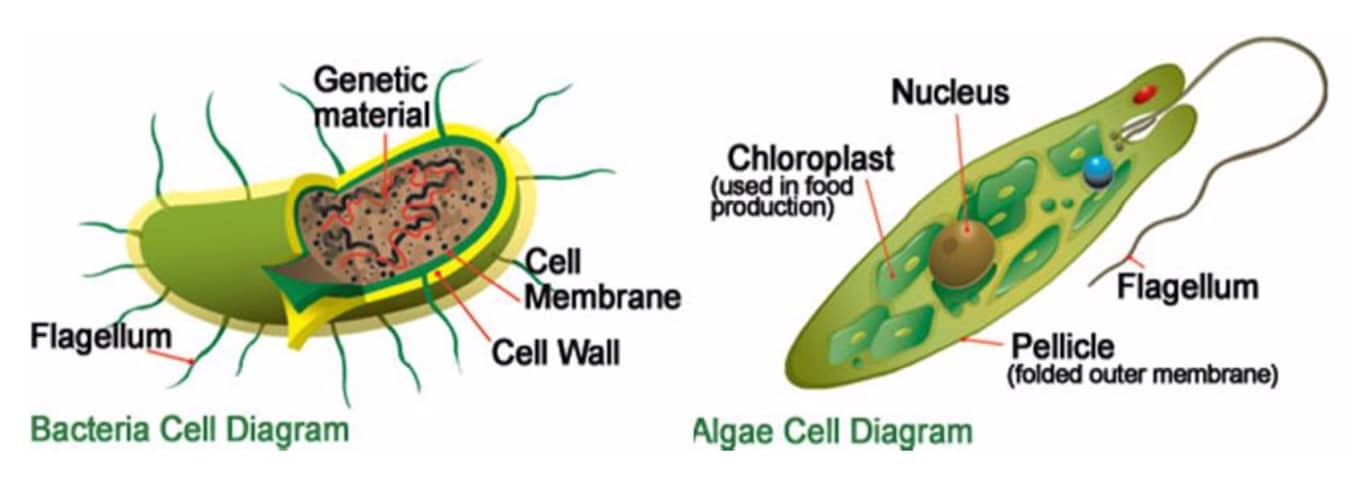

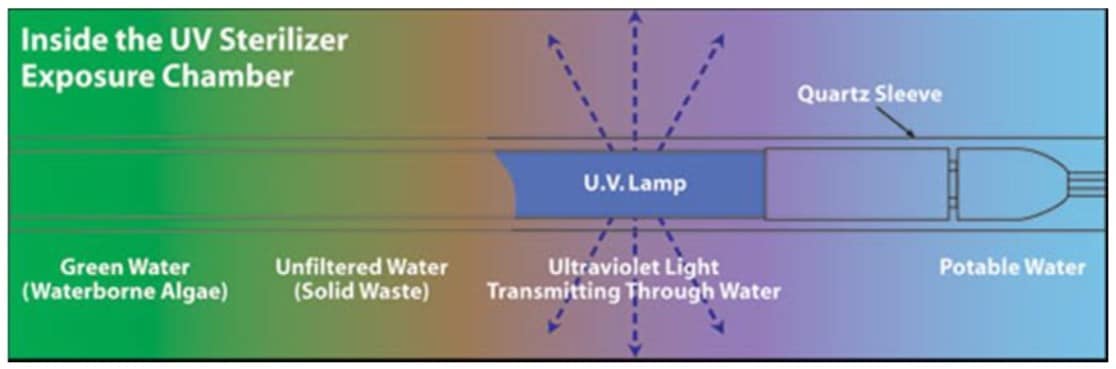

It is critical to first identify the microorganism. Each type of microorganism requires a specific UV-C radiation exposure rate to successfully complete the disinfection process. The targeted microorganism must be directly exposed to the UV-C radiation long enough for the radiation to penetrate the microorganism’s cell wall. However, it takes only seconds for UV-C light rays to inactivate waterborne microorganisms by breaking through the microorganism’s cell wall and disrupting their DNA. This often totally destroys the organism, or at the very least will impair its ability to reproduce.

The UV Lamp... the Source of UV

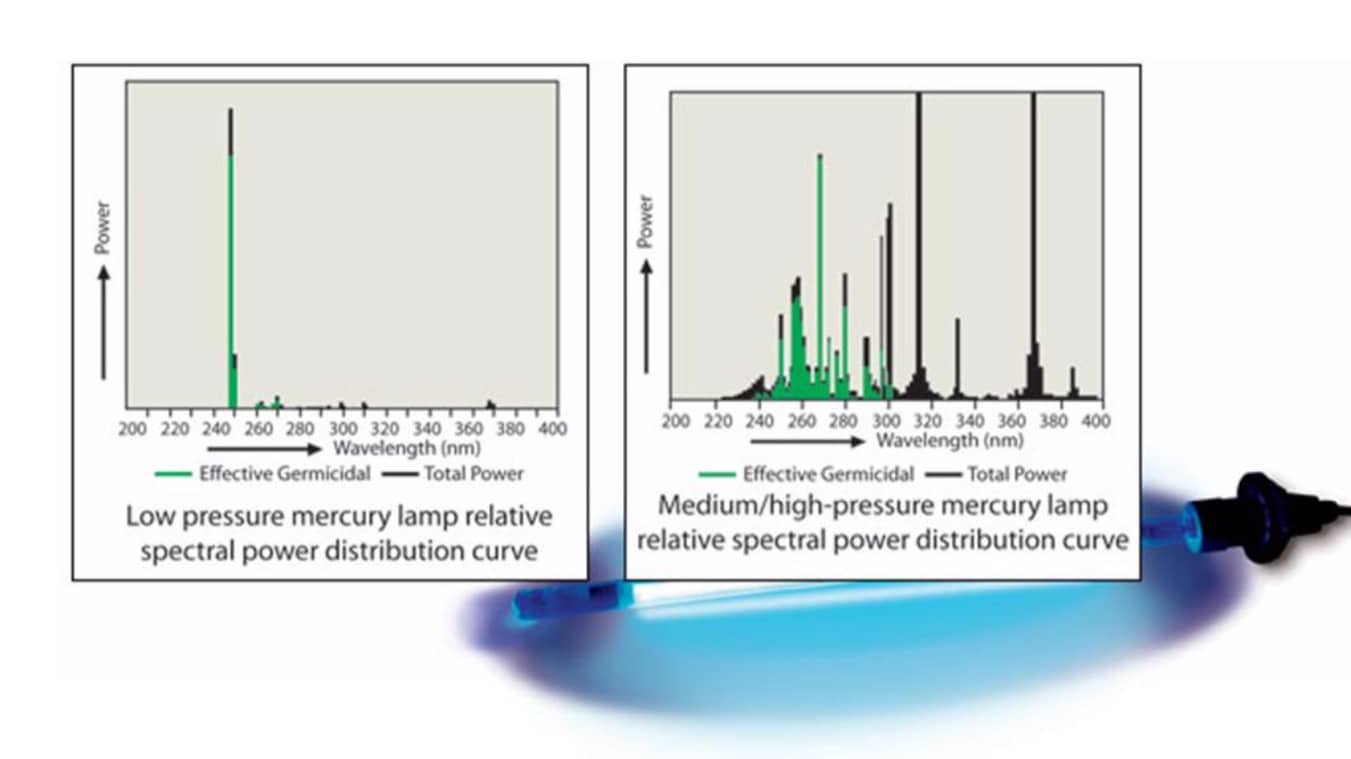

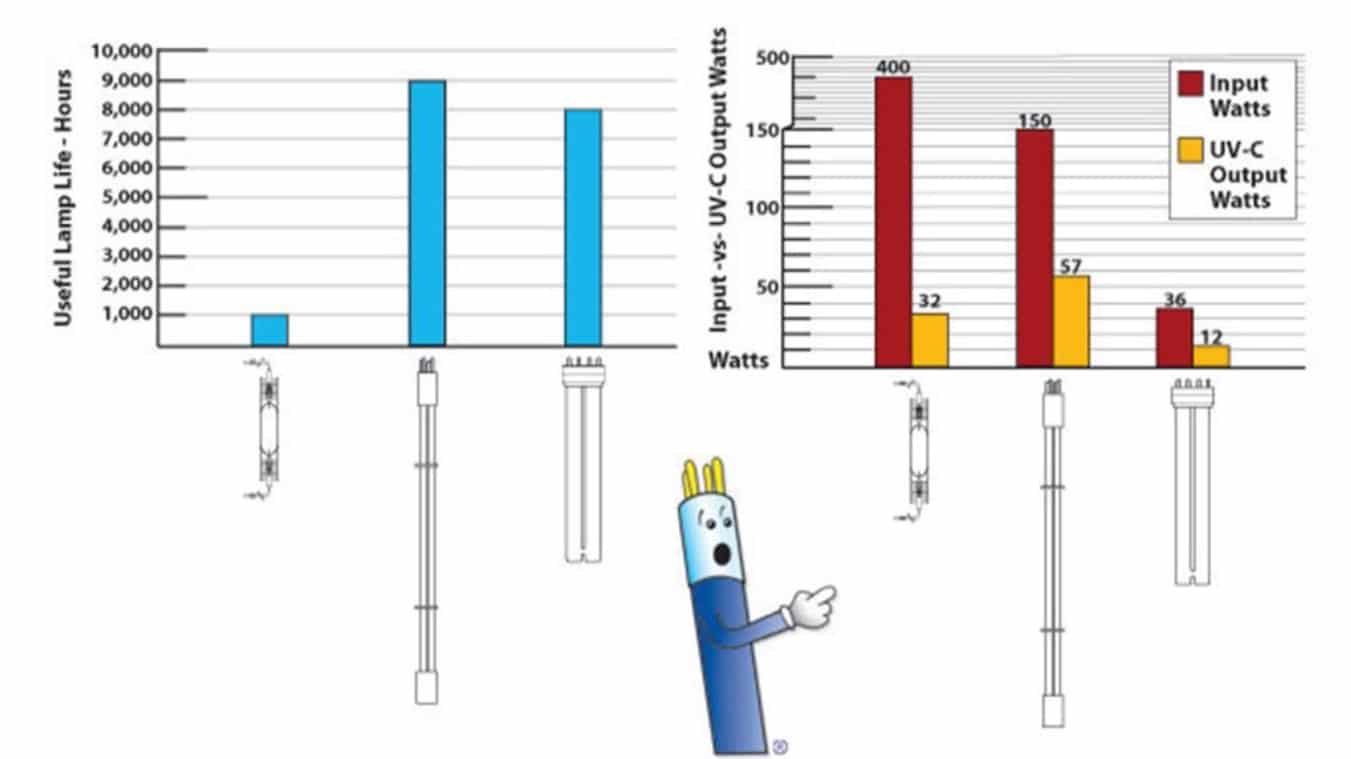

UV light sources primarily come as low-pressure or medium/high-pressure lamps. Low-pressure lamps produce virtually all of their UV output at a wavelength of 254 nanometers-very close to the peak germicidal effectiveness curve of 264 nanometers. These lamps generally convert up to 38% of their input watts into usable UV-C watts. This is much higher than other classes of lamps. (i.e. a 150-watt low-pressure lamp will have approximately 57-watts of UV-C power.) Low-pressure lamps typically run on low-input power currents of 200 to 1,500 milliamps and operate at temperatures between 100 and 200 degrees Fahrenheit. They have a useful life of 8,000 to 12,000 hours depending on the operating current of the lamp.

Medium/high-pressure lamps produce wavelengths widely ranging from 100 nanometers to greater than 700 nanometers, well into the visible light spectrum. These lamps are very poor producers of usable germicidal wavelengths; they generally convert only up to 8% of their input watts into usable UV-C watts. (i.e. a 400-watt medium-pressure lamp will have approximately 32-watts of UV-C power. The remaining 368-watts are converted into heat and visible light.) Medium/high-pressure lamps typically run on high-input power currents of 2,000 to 10,000 milliamps and operate at temperatures between 932 and 1,112 degrees Fahrenheit. They have a useful life of only 1,000 to 2,000 hours depending on the lamp’s operating current. As you can see from these comparisons, low- pressure lamps perform safely and efficiently. They are the better option for use in UV sterilization.

Low-pressure UV lamps come in many different styles and lengths. As a general rule, the longer the lamp, the greater amount of UV the water will receive because it will be exposed to the UV source for a longer period of time.

UV Lamp Length + UV-C Output + Useful Lamp Life = Lamp Value

- UV lamp length is a critical performance factor that helps establish UV exposure.

- Evaluating UV lamp performance based on input watts is inaccurate! The “Input -vs- UV-C output Watts Chart above demonstrates the poor germicidal value of med-pressure lamps compared to low-pressure type UV lamps. Low-Pressure UV lamps convert approximately 38% of their input watts into UV-C output watts while the medium- pressure UV lamps convert 8%. Low-pressure style UV lamps offer greater germicidal value than medium pressure lamps for this reason.

- Knowing when to replace UV lamps is critical to achieving a consistent UV disinfection dose, but not all lamps offer the same useful operating life!

Design of the Water Exposure Chamber

The design of the water exposure chamber is completely overlooked by some manufacturers, but it is key to successful operation. The distance UV light energy has to travel from the surface of the lamp to the inner wall of the UV’s water containment vessel determines how much UV the water will receive. This is known as the “UV dose rate.” The amount of water passing through the UV filter ultimately determines the unit’s actual UV dose rate, which is expressed in microwatt’s per second per square centimeter or (u-watts-sec/cm2). When selecting a UV Sterilizer for your application:

- Make sure the UV lamp is positioned between the water inlet and outlet ports of the unit’s water containment vessel. Any portion of the UV lamp(s) not located between the water ports is useless. When calculating the UV’s performance data, only the ARC length located between the water ports can be applied to the calculation, reducing its capabilities if portions of the lamp are not between the ports.

- Select the unit with the largest diameter water containment vessel in the wattage you are considering. A unit with a larger diameter will always have a greater contact time. (For example, a 25-watt model with a 3″ diameter housing will flow more water than a 2″ housing model.)

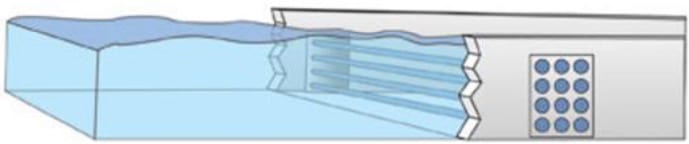

Single UV Lamp Array Diagram

Multiple UV Lamp Array Diagram

Open-Channel UV Lamp Array Diagram

- Make sure the unit you are considering uses a quartz sleeve. A quartz sleeve isolates the UV lamp from the water to avoid a short circuit path for the lamp’s electrical power. It also allows the lamp to operate at its optimum temperature by acting as an insulator.

- Does the manufacturer list water flow rates at the end of a lamp’s life or the beginning? Most UV manufacturers give a water flow rate, but do not indicate whether it applies to a new lamp or to one that is at the end of its useful life. Try to find a manufacturer that includes the water flow rate in the unit’s end of lamp life rating. The end of lamp life rating takes into account the lamp losing UV-C output due to age so it is a more realistic prediction of how the unit will perform.

- Do the manufacturer’s water flow rates account for the reduced effectiveness UV light has when treating green water? This information should be listed as some type of percent transmissibility rate or absorption coefficient (decimal value). Units that account for green water will have lower water flow rates.

UV Transmittance

UV transmittance is also largely overlooked, but it is one of the most critical factors in determining the ability of a UV sterilizer to treat a given volume of water. Regardless of the type of UV light source used, any body of water containing impurities will adsorb UV energy. Green water, water plagued by algae and microorganisms, will absorb the UV energy emitted by our UV light source in proportion to its density (or how green the water is). The greater the amount of algae in the water, the more of a reduction in percent transmittance. Percent transmittance is the ability of a body of water to be effectively treated by a UV light source. This value indicates the quality of the water being treated. The higher the percent transmittance, the easier the UV sterilizer will be able to treat the water at a given flow rate. A lower percent transmittance means the UV sterilizer will be less effective in dealing with the algae problem. If the sterilizer’s water flow rates have not been calculated with a reduced percent transmittance rate, the unit will have considerable trouble dealing with an algae bloom.

Water flow rate through the UV's contact chamber

A sound UV sterilizer design revolves around the careful selection of lamp type, lamp length, lamp position, and body diameter. These factors, together with the intended water flow rate, percent transmittance of the water to be treated, and UV dose rate needed to kill the targeted microorganism should be your basis for the selection of a unit for your pond. When researching which type of UV sterilizer to purchase, remember the criteria laid out in this article, read the manufacturer’s literature, ask questions, and most of all ask yourself, does this information make sense to me? If not, consider another UV manufacturer.

The Importance of Water Sterilisation