Removing Iron From Water

An overview of Iron related bacteria in bores

IRON IN WATER. Iron is one of the most common contaminants facing owners of wells. There is a remedy. Please remember that Iron is one of the major problems with your water supply. Many Thanks to John @ Fresh Water Systems, USA, for a very clear and honest description of the Iron in Water issue. Coolabah Water, Wagga Wagga, Australia. Contact Bernard For More Professional Information Telephone 0429 651 116

The phenomenon that is called IRON BACTERIA is actually bacteria feeding off soluble iron and manganese creating a slime over the inside of pipes. THIS also mixes with CALCIUM which is naturally occurring in most bore supplies.

The calcium turns to a crystal as normal and this combination of CALCIUM – IRON – BACTERIA produces a thick red sediment which causes multi-impeller discs to plug up with the residue.

This is particularly prone to occur in submersible bore-hole pumps and also the inside walls of delivery pipes and usually seriously affects water delivery performance or stops the flow completely.

Range of water treatment services for

Bacteria

The bacteria contamination cannot be killed outright in the bore but needs to be kept under control. The bacteria contamination is a high factor in the overall problem, but the bacteria alone does not cause it.

Iron

The iron that feeds the bacteria cannot be removed from the aquifer but can be controlled in the bore and bacteria just loves feeding off iron.

Calcium

Calcium is also a major part of the issue. Its natural ability to turn to a solid, or to a crystal very quickly is as much of the problem as the other two, bacteria and iron.

Calcium forms a crystal, then mixes with the iron and the bacteria, making a brown sludge which forms inside pump impellers and pipes and the problems start.

If you were to remove this brown sludge from a bore pump or pipe and analyse this you can expect the percentage of calcium in the sludge to be as high as 80% plus.

Removing bacteria only

If the bacteria contamination in bore water is disinfected or removed where iron bacteria is present, then the brown residue would become quite hard and dry scale.

Leave the bacteria active and this same residue that causes so much heartache will remain quite soft and the higher the bacteria contamination, the sloppier the brown sediment.

Iron accelerates bacteria growth

The iron feeds the bacteria and accelerates its growth. The iron cannot be removed from the aquifer but it can be turned to a solid. the best remedy for this is using Envrobore. video link and Brochure

Treatment is needed

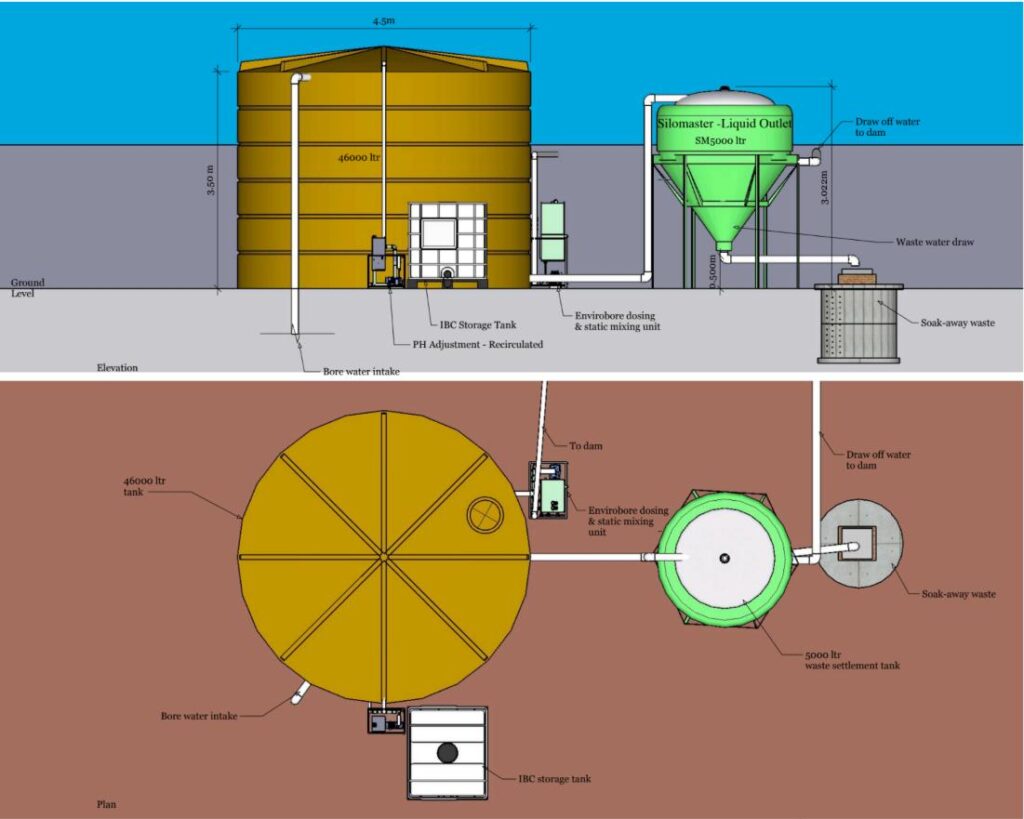

Coolabah water treatment need two systems in place for dealing with bacteria, iron and calcium where it affects bore pumps. Iron cannot be filtered out and can only be removed by oxidation.

This can be treated down the borehole, where the problem starts. The bore water will lose its clarity and become slightly or heavily brown, as it turns to a solid. This cloudy water is quite harmless for such purposes as stock water or irrigation.

Air cannot be introduced into the piping system to oxidize the iron because it will cause cavitation in the pump and damage the impeller(s). The cheapest and most successful method is to Envirobore. video link and Brochure

Will chlorine succeed

No, as is pH dependant and will shorten the pump life and is harmful to pump seals.

Acid treatment

No, Not Recomended

Calcium problem

This needs to be treated also. If you were to remove the iron and bacteria successfully, you could be left with white scale down the pipe-work and other plumbing and this is not desirable.

Magnetic water treatment

Coolabah water treatment use magnetic water treatment in a very powerful form called the Coolabah Fluid Reactor. Its task is to break up the calcium build-up after the bore pump. It does this by preventing the calcium from crystallising out as a solid. This is achieved by inducting a DC voltage charge off the permanent magnetic material that is the heart of the unit.

This forces the calcium to remain fully soluble and not deposit, and it will reverse the existing calcium build-up. To make this all happen, Coolabah water treatment make up a kit that suits each problem bore and allows part of the bore water to re-circulate once or twice per day by valve controls or simply by injecting straight down the bore, and a dosing pump applies the chlorine to treat the pump and the bore.

This can become a very necessary and permanent treatment to keep the pump alive as a cost-effective measure. The Coolabah Fluid Reactor has ongoing value for bore users and is an excellent investment as it has no ongoing operating or maintenance costs. This treatment is applied at the bore-head and will treat all the water coming out as well as the re-circulated treated water.